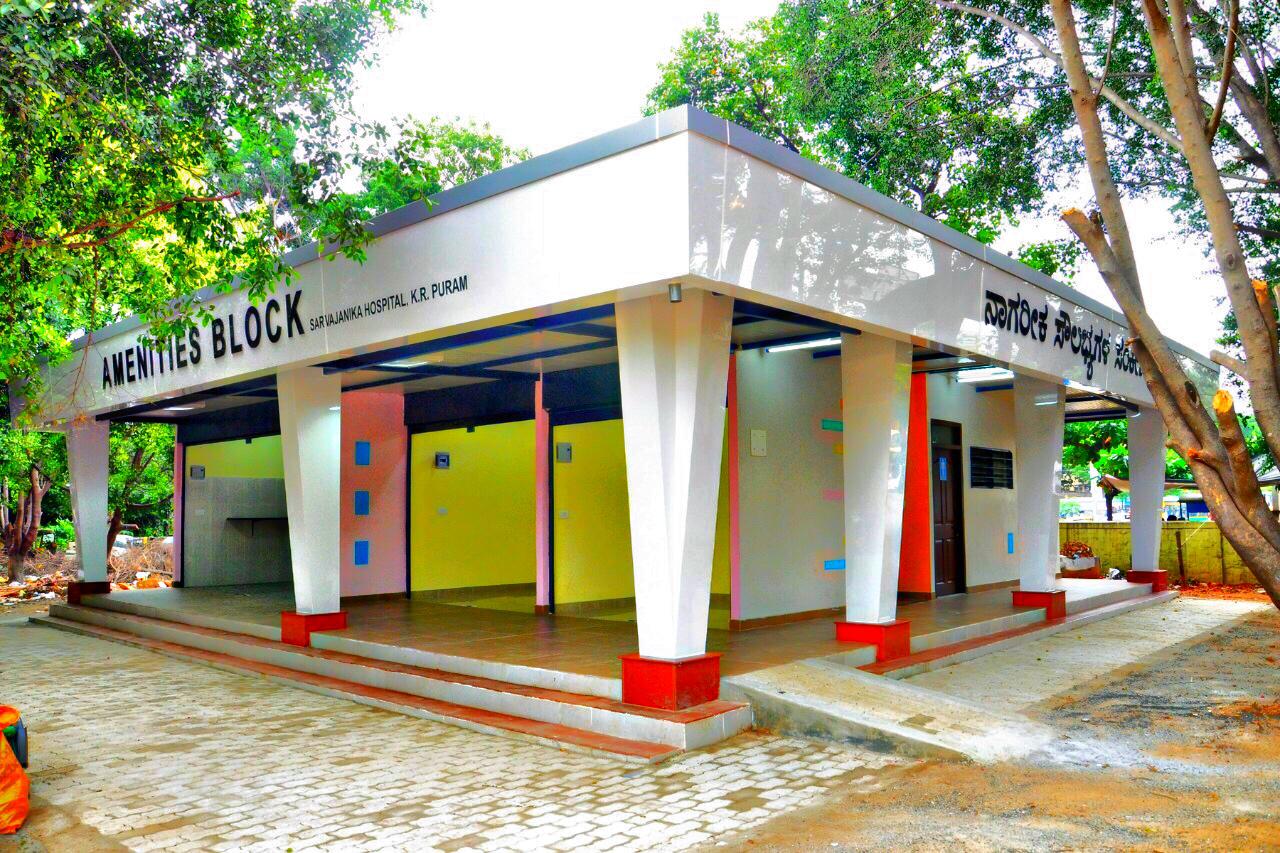

80 days completion

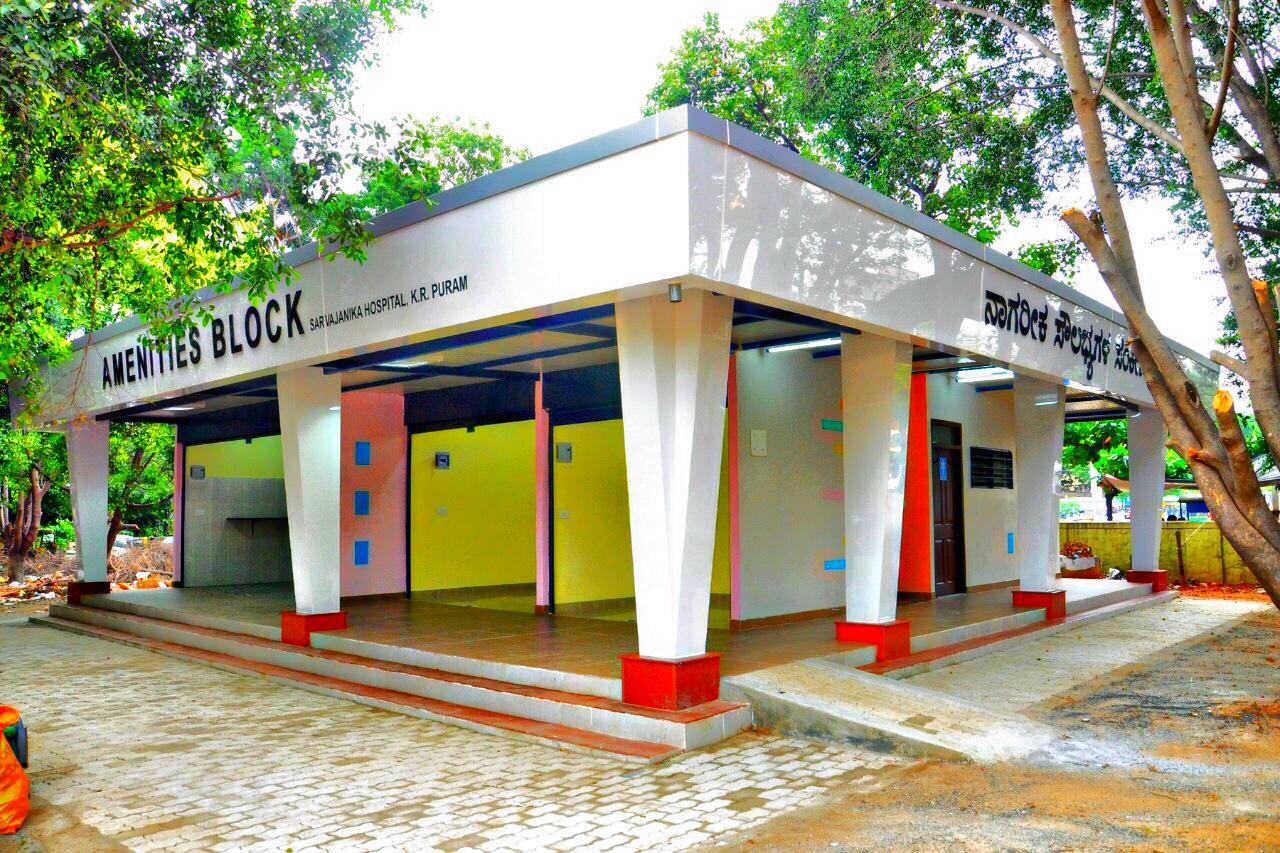

60 days completion

90 days completion

2 day completion

Precast

Precast concrete is a construction product produced by casting concrete in a reusable mold, or "form," which is then cured in a controlled environment, typically in a temperature- and humidity-controlled chamber. This produces a high-quality finished product that is stronger, more durable, and more consistent than site-cast concrete.

How It Works

Design

Precast structures with Shear wall construction, Column wall, beams & Hollow core slab is designed by our team.

Production

The precast factory has specialist workshops for the fabrication of moulds as per the shop drawings and for the production of jig-built reinforcing cages and Electrical & plumbing connections. Carefully specified concrete is poured and vibrated as per the international standard. The product exhibits a high degree of dimensional accuracy and quality of finish.

Transporation

The finished precast components are stacked on clean battens or plastic pads positioned to suit the design of the component. The components are delivered to site as per the erection plan on A frame or Flat bed trailers to ensure that components are ready for instant erection.

Erection

The components are erected straight from the trailer most of the times. This leads to faster erection times with reduced on-site activity. Joint grouting and finishing will be done using internationally approved materials.

Benefits

Precast Yard

All the elements are manufactured at our Precast yard and transported to the project site for Erection.

Precast Manufacturing Process at the Precast Yard

There are 5 steps involved in the manufacturing of a precast building. All of these steps are carried out at our mobile precast manufacturing unit in Mysore before being transported to the project site for erection.

Projects

We are future-ready! Are you?

Reach out to us to get your project future-ready! Drop by for a visit at our office, or fill out the form, and we'll get in touch with you shortly.

#74, Sandesh Arcade Sahukar chennaih Road, 17th Main Road, Kuvempunagara North, Saraswathipuram, Mysuru, Karnataka 570009

+91 9036130016, +91 8970070117

info@pgsetty.com, pgsmysore@pgsetty.com